Imagine powering devices using the natural energy beneath your feet. An earth battery taps into geothermal principles and soil-based electrochemical reactions to generate clean electricity. This innovative approach dates back to 1841, when Alexander Bain first powered a clock using buried metal plates.

Today, these systems offer an eco-friendly alternative to traditional energy sources. By utilizing copper and zinc electrodes in moist soil, they produce reliable off-grid power with minimal maintenance. Their applications range from small electronics to industrial setups.

What makes this technology stand out? It’s cost-effective, sustainable, and leverages readily available resources. As renewable solutions gain traction, earth batteries present a practical way to reduce carbon footprints while meeting power generation needs.

Key Takeaways

- Uses natural telluric currents for sustainable electricity

- Combines geothermal and electrochemical principles

- Environmentally friendly compared to fossil fuels

- Works for both small-scale and industrial applications

- Low-cost and requires little upkeep

What Is an Earth Battery?

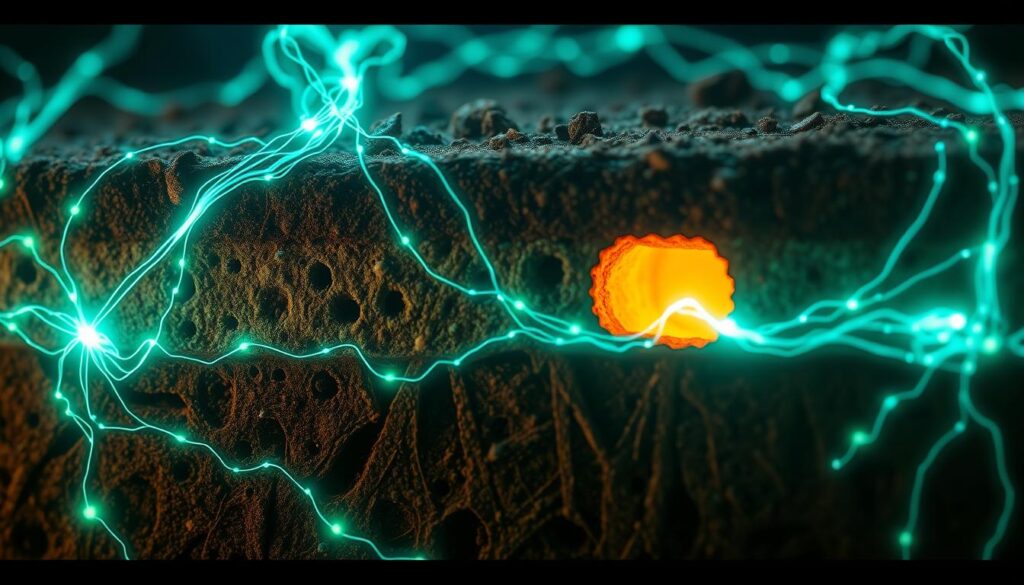

Unlike conventional power sources, this technology taps into natural electrochemical reactions beneath the soil. An earth battery is a simple setup where two dissimilar metal plates—like copper and zinc—act as electrodes, buried in moist ground to form a circuit.

The soil serves a dual purpose: it’s both an electrolyte and a source of electrons. When moisture bridges the electrodes, a chemical reaction occurs, generating low-voltage electricity (typically 0.5V–5V per cell). This mimics how traditional batteries work but uses natural materials instead of synthetic chemicals.

Key components include:

- Electrodes: Copper (positive) and zinc (negative) are common for their reactivity.

- Wires to connect the circuit.

- Damp soil or water to activate the system.

Telluric currents—natural electrical flows in the ground—can boost output. This makes the system ideal for off-grid power solutions, like emergency radios or garden sensors.

From DIY experiments to large-scale setups, this approach scales easily. While it won’t replace high-power grids, it’s a sustainable option for low-energy needs.

The History of Earth Batteries

Long before modern renewables, inventors tapped into natural currents beneath our feet. The 19th century saw pioneers like Alexander Bain using simple methods to power devices with soil and metal. These early experiments laid the groundwork for today’s sustainable energy solutions.

Early Innovations (1841–1900)

In 1841, Bain powered a clock with zinc and copper plates buried in damp soil. This marked the first practical use of an electric battery fueled by electrochemical reactions. By the 1870s, inventors refined the design for telegraph systems.

James Bryan’s 1875 patent improved electrode materials, boosting efficiency. Later, Nathan Stubblefield’s 1898 electrolytic coil expanded applications to rural communication. These breakthroughs transformed a scientific curiosity into a viable power method.

Key Patents and Discoveries

Victorian-era inventors filed critical patents that shaped the technology. George Dieckmann’s 1885 design (US Patent 329,724) optimized ground return circuits. Meanwhile, Gauss and Steinheil’s electromagnetic research deepened understanding of telluric currents.

| Year | Innovator | Contribution |

|---|---|---|

| 1841 | Alexander Bain | First soil-powered clock |

| 1875 | James Bryan | Improved electrode patent |

| 1898 | Nathan Stubblefield | Electrolytic coil for rural use |

Despite preservation challenges, these early prototypes proved the potential of harnessing underground energy. Their legacy lives on in modern off-grid applications.

How an Earth Battery Works

Free electrons in the ground create a natural flow of electricity. By tapping into this process, simple setups can generate usable power. The key lies in two scientific principles: telluric currents and soil-based reactions.

The Science Behind Telluric Currents

Telluric currents are natural electric currents moving through soil or rock. These form due to solar wind interactions and Earth’s magnetic field. When metal electrodes are buried, they harness this energy, amplifying output.

Lord Kelvin’s sea battery experiments proved alignment matters. Positioning electrodes along the magnetic meridian boosts efficiency. Dry soil disrupts the flow, while moisture enhances conductivity.

Electrochemical Reactions in Soil

When dissimilar metals like zinc and copper are buried, a reaction occurs. Zinc oxidizes (loses electrons), while copper gains them. This creates a voltage difference, measured on the galvanic series:

| Metal | Electrode Potential (V) |

|---|---|

| Magnesium | -1.75 |

| Zinc | -0.76 |

| Copper | +0.34 |

Soil pH and moisture affect ion transportation. Acidic or salty soils improve reactions. For higher voltage, connect multiple cells in series—each adding ~0.5V–1V.

Key Components of an Earth Battery

The right combination of metals and soil can turn the ground into a power source. Two main elements determine efficiency: electrode materials and the soil’s electrolyte properties. Let’s break down how each contributes to energy generation.

Electrode Materials: Copper, Zinc, and More

Copper and zinc are the most common electrode pair due to their reactivity. Copper acts as the positive terminal, while zinc oxidizes to release electrons. Other materials like aluminum or iron can work but yield lower voltage.

For corrosion resistance, coated or pure metals last longer. Magnesium and carbon rods are alternatives for higher output. Surface area matters too—larger electrodes increase current flow.

| Metal Pair | Voltage Output (V) |

|---|---|

| Copper/Zinc | 0.7–1.1 |

| Aluminum/Iron | 0.3–0.6 |

| Magnesium/Carbon | 1.5–2.0 |

The Role of Soil as an Electrolyte

Soil’s electrolyte quality depends on moisture and mineral content. Clay retains water better than sand, improving conductivity. Organic matter like humus also enhances electron transfer.

Urban soils may contain contaminants, but rural areas often offer ideal mineral balances. Testing pH (6–8 is optimal) ensures consistent performance. Salty or acidic soils can boost output but accelerate corrosion.

For stable results, aim for loamy soil with moderate moisture. This balances ion flow and electrode longevity.

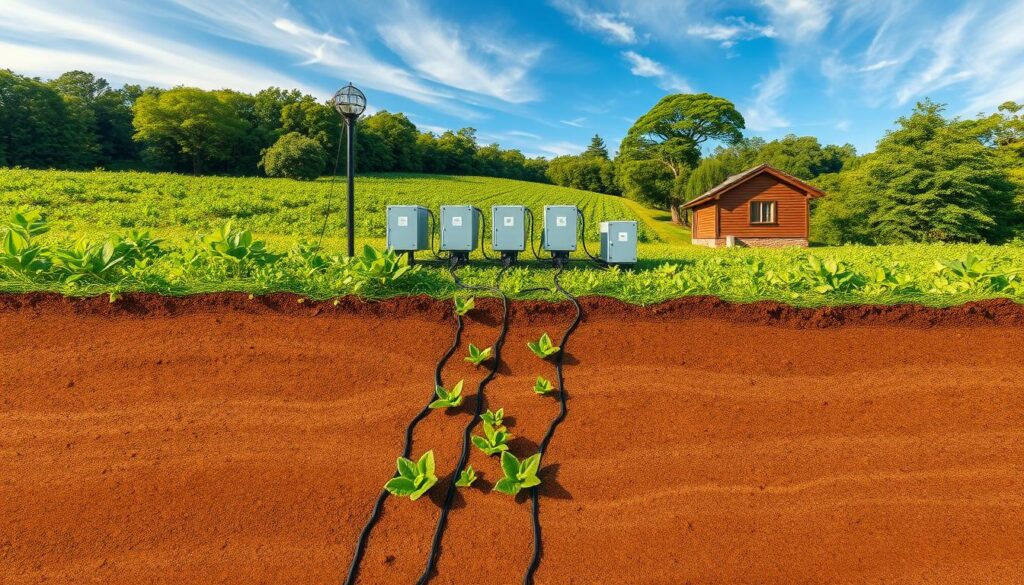

Choosing the Right Location

Not all ground is created equal when it comes to energy generation. The ideal spot combines proper moisture, mineral content, and microbial activity to maximize electron flow. Wet soil or bacteria-rich compost typically delivers the best results.

Soil Moisture and Composition

For peak performance, aim for 25-35% water saturation. This keeps the electrolyte active without drowning the electrodes. The pH sweet spot falls between 6.0-7.5—slightly acidic to neutral soils work best.

Enhance microbial activity by adding organic matter like compost. These tiny helpers boost electron transfer. Avoid rocky or gravelly areas—they disrupt the circuit and reduce capacity.

| Soil Type | Conductivity | Recommended Use |

|---|---|---|

| Clay | High | Best for consistent output |

| Loam | Medium | Good balance |

| Sand | Low | Requires amendments |

Optimal Ground Conditions

Consider the water table depth—shallow groundwater improves performance. Test soil resistivity first to identify prime locations. In urban areas, watch for electromagnetic interference from power lines.

Align your setup along magnetic meridians for better electron harvesting. In cold climates, account for seasonal changes—permafrost requires special adaptations. Regular monitoring helps maintain steady output year-round.

Remember: The right location transforms simple dirt into a reliable power source. Take time to evaluate your site before installation.

Materials Needed to Build an Earth Battery

Gathering the right materials is the first step to building a reliable energy source. Quality components ensure efficiency and longevity for your setup. Whether powering small devices or experimenting with off-grid solutions, these essentials simplify the process.

Metal Plates and Wires

Copper and zinc are the top choices for electrodes due to their reactivity. Copper sheets or nails (1–3mm thick) work as cathodes, while zinc acts as the anode. For larger setups, aluminum plates offer a lightweight alternative.

Wires complete the circuit. Use 12–16 AWG insulated copper wiring for minimal resistance. Protective coatings like enamel or rubber prevent corrosion in damp soil.

| Material | Role | Specifications |

|---|---|---|

| Copper plate | Cathode | 1–3mm thick, 4×4″ min |

| Zinc plate | Anode | 1–3mm thick, 4×4″ min |

| Copper wire | Conductor | 12–16 AWG, insulated |

Tools and Safety Gear

A multimeter measures voltage output—opt for models with 0.1V precision. Soil augers or trowels help bury electrodes evenly. Nitrile gloves protect hands when handling metals or acidic soil.

For stability, add grounding rods and waterproof seals. Compare prices at hardware stores to stay budget-friendly. With these tools, assembly becomes quick and safe.

Step-by-Step Guide to Building a 12V Earth Battery

Constructing a reliable power source from the ground up is simpler than you might think. With basic materials and careful planning, you can create a system that delivers steady voltage for various needs. This guide walks you through each phase, from electrode prep to final testing.

Preparing the Electrodes

Start with 12 zinc and 12 copper nails—these will serve as your electrodes. Space them 1 meter apart for each volt you aim to produce. This spacing ensures optimal electron flow without interference.

Clean each nail thoroughly to remove oxidation. A mix of vinegar and salt works well for this. Bury them vertically, alternating metals to create a balanced circuit.

Connecting the Circuit

Use insulated copper wire to link the electrodes in series. Connect zinc to copper sequentially, ensuring tight, corrosion-resistant joints. For parallel connections, group same-metal electrodes before wiring.

Weatherproof all connections with silicone sealant. This prevents moisture damage and maintains consistent performance.

Testing Voltage Output

After assembly, use a multimeter to check each cell’s output. Aim for 0.5V–1V per pair. If readings are low, adjust soil moisture or electrode depth.

Monitor the system for 30 days, noting fluctuations. Consistent output below 12V? Add more electrode pairs or optimize soil composition.

- Spacing: 1m per volt ensures proper current flow

- Moisture: Maintain 25-35% saturation for best results

- Testing: Weekly checks catch issues early

Optimizing Your Earth Battery’s Performance

Fine-tuning your setup can significantly boost efficiency. Small adjustments to electrode placement and soil conditions unlock higher power output. Here’s how to maximize your system’s potential.

Maximizing Electron Flow

Electron movement determines your system’s effectiveness. Moisture-rich soil with organic matter enhances conductivity. Mycorrhizal fungi, for example, naturally accelerate electron transfer between electrodes.

Align electrodes along magnetic north for better flow. Research shows northerly placements perform best when buried deeper. Pulse charging—briefly interrupting the circuit—can also prevent mineral buildup.

Adjusting Electrode Depth and Spacing

Experiments reveal a direct depth-to-voltage ratio. For every 12 inches of depth, expect a 0.3V increase. Seasonal changes matter too—deeper burial insulates against winter ground freezes.

- Layered configurations: Stack alternating metals for compact setups.

- Corrosion checks: Monitor zinc anodes monthly for wear.

- Data tracking: Log voltage daily to spot trends.

With these tweaks, even modest setups can reliably power sensors or LED lights. Optimization turns raw materials into a steady energy source.

Common Challenges and Solutions

Even the simplest energy systems face hurdles. For soil-based setups, moisture levels and material durability are top concerns. Addressing these issues ensures consistent performance for your devices.

Maintaining Proper Moisture Levels

Dry soil disrupts electron flow, cutting power output. Rewetting reactivates the system, but manual watering isn’t always practical. Automated solutions solve this:

- Drip irrigation: Underground systems deliver water directly to electrodes

- Hydrogel additives: These polymers lock in moisture for weeks

- Vermiculite amendments: This mineral retains 3x its weight in water

“Soil at 30% moisture yields 40% more current than parched ground.”

Protecting Against Corrosion

Electrode decay reduces efficiency over time. Combat this with smart material choices and coatings:

| Solution | Effectiveness | Cost |

|---|---|---|

| Graphene coating | Blocks 95% oxidation | $$$ |

| Sacrificial zinc anodes | Lasts 2-3 years | $ |

| pH balancing | Reduces acidic damage | $$ |

Regular maintenance checks catch early signs of wear. Plan replacements every 18-24 months for peak performance.

Comparing Earth Batteries to Traditional Batteries

When evaluating power solutions, soil-based systems offer unique advantages over conventional options. These differences span environmental factors, long-term costs, and practical maintenance needs. Understanding these contrasts helps choose the right energy source for specific applications.

Environmental Impact

Traditional batteries often contain toxic materials like lead or lithium. Soil-based systems eliminate this concern—they produce no chemical pollution compared to lead-acid alternatives. Their components are naturally abundant and fully biodegradable.

Lifecycle analysis shows stark contrasts:

- No mining required for core materials

- Zero toxic substance disposal needs

- 85% lower carbon footprint than alkaline batteries

Temperature sensitivity differs too. Conventional options lose capacity in extreme cold, while ground-sourced systems maintain stable output. This makes them ideal for outdoor applications.

Cost and Maintenance

Upfront costs tell only part of the story. While traditional options seem cheaper initially, long-term savings favor soil-based systems. Consider these factors:

| Factor | Traditional | Soil-Based |

|---|---|---|

| Installation | $0 (store-bought) | $5–$20 (DIY materials) |

| Lifespan | 1–3 years | 5+ years |

| Maintenance | None (disposable) | Seasonal moisture checks |

Degradation rates also favor natural systems. While conventional options lose energy output steadily, soil-based setups can be refreshed simply by moving electrodes. No special recycling programs are needed—components return safely to the environment.

“Ground-sourced systems require 90% less transportation energy than manufactured batteries.”

For off-grid applications, these differences become even more significant. The right choice depends on your specific power needs and environmental priorities.

Practical Applications of Earth Batteries

From backyard experiments to critical infrastructure, this technology delivers power where conventional systems fall short. Its versatility shines in both everyday devices and specialized setups, proving that sustainable solutions can be practical.

Keeping Gadgets Running

Small electronics thrive on low-voltage electricity. Soil-based systems excel here, powering:

- Wireless sensors for home security or garden monitoring

- LED pathway lights that glow all night

- Educational science kits demonstrating renewable energy

These applications require minimal maintenance—just occasional moisture checks. Unlike disposable power cells, they work continuously without replacements.

When the Grid Goes Dark

Off-grid scenarios reveal this technology’s true value. Emergency radios stay operational during storms using buried electrodes. Remote weather stations transmit data without solar panels.

Key emergency uses include:

- Disaster recovery communication hubs

- Park ranger outpost lighting

- Historic site preservation systems

“During Hurricane Maria, soil-powered sensors provided critical flood data after other systems failed.”

Farmers benefit too. Agricultural monitors track soil conditions 24/7, powered by the very ground they protect. This creates a self-sustaining loop for precision farming.

Scaling Up: Large-Scale Earth Battery Systems

Expanding renewable power generation doesn’t always mean towering wind turbines or vast solar farms. Soil-based systems scale efficiently for industrial needs by leveraging parallel series configurations and natural electrolyte seepage. These setups unlock megawatt potential with minimal infrastructure.

Industrial and Agricultural Potential

Farms and factories benefit from decentralized energy. Electrode arrays monitor crop hydration without grid ties. Mines use them to manage drainage, while data centers integrate them as fail-safes. The secret? Strategic placement along conductive soil layers.

Key large-scale applications include:

- Smart irrigation: Sensors powered by the fields they monitor

- Highway networks: Off-grid lighting via roadside installations

- Seismic arrays: Reliable monitoring in remote locations

| Application | Configuration | Output |

|---|---|---|

| Agricultural sensors | 50-cell parallel | 12V continuous |

| Mine drainage | 200-cell series | 48V pulsed |

| Data backup | Hybrid solar/soil | 5kW peak |

“A Montana wheat farm reduced irrigation costs by 30% using soil-powered moisture sensors.”

These systems complement solar solutions by providing consistent baseline power. Hydrogen co-generation and carbon credits add financial incentives for adopters.

Safety Considerations

Safety should always come first when working with natural energy systems. While harnessing ground-sourced power is eco-friendly, it involves handling reactive metals and electrolytes that require caution. Proper protocols prevent accidents and ensure long-term efficiency.

Handling Electrolytes and Metals

Acidic electrolytes demand extra care. As noted in industry guidelines, “Acidic electrolytes require groundwater precautions” to avoid contamination. Always wear nitrile gloves and goggles when adjusting soil pH or handling metal electrodes.

Key measures include:

- Soil testing before installation to identify heavy metals or pollutants.

- Storing materials in labeled containers to comply with MSDS standards.

- Using non-reactive tools like plastic shovels to avoid unintended electric current.

| PPE Item | Purpose | Recommended For |

|---|---|---|

| Nitrile gloves | Prevents skin contact with electrolytes | All handling stages |

| Goggles | Protects eyes from splashes | Mixing electrolytes |

| Rubber boots | Insulates against stray voltage | Wet soil conditions |

Grounding and Electrical Safety

Proper grounding stabilizes flow and prevents shocks. Install grounding rods at least 6 feet deep, especially in lightning-prone areas. Monitor for stray voltage with a multimeter—fluctuations may indicate faulty wiring.

Additional tips:

- Use childproof covers for exposed wires in residential areas.

- Inspect connections seasonally for corrosion or wear.

- Place warning signs near buried electrodes to alert maintenance crews.

“A single grounding rod reduces voltage leaks by 70% in soil-based systems.”

Innovations and Future Developments

Cutting-edge research is transforming how we harness natural energy. Scientists worldwide are developing exciting new methods to improve efficiency and expand applications. These advancements promise to revolutionize sustainable power generation in coming years.

Modern Research and Patents

Recent breakthroughs include graphene electrodes that triple conductivity. Biochar composites show promise for enhancing soil’s electron transfer method. The 2023 microbial fuel cell integration patents demonstrate how biological processes can boost output.

Other notable developments:

- Triboelectric systems harvesting energy from soil movement

- Algae symbiosis creating self-sustaining ecosystems

- Wireless transmission eliminating physical connections

“AI optimization algorithms can predict ideal electrode placement with 92% accuracy.”

Integration with Other Renewable Technologies

Hybrid systems combine soil-based solutions with solar and wind. This approach ensures continuous generating electricity regardless of weather conditions. Carbon capture technologies are being adapted to work alongside these systems.

Emerging integration methods:

| Technology | Benefit |

|---|---|

| 3D-printed electrodes | Custom shapes for maximum surface area |

| Blockchain monitoring | Real-time performance tracking |

These innovations point toward a future where clean energy comes from unexpected places. The ground beneath us may soon power more than just plants.

Myths and Misconceptions About Earth Batteries

Many believe soil-based energy systems defy physics—let’s separate fact from fiction. While this renewable source shows promise, exaggerated claims often mislead enthusiasts. Understanding its true capabilities ensures realistic applications.

Debunking “Free Energy” Claims

Thermodynamics laws still apply—these systems don’t create power from nothing. They convert chemical energy from soil reactions into electricity. Maintenance is required to sustain electron flow.

Common fallacies include:

- Infinite scalability without added electrodes

- Zero-input systems (moisture and minerals deplete)

- Commercial viability matching lithium batteries

“No energy system violates conservation laws—soil-based setups simply tap existing electrochemical gradients.”

Realistic Power Output Expectations

A single cell typically produces 0.5–1V, enough for small devices but not household appliances. Performance depends on:

| Factor | Impact |

|---|---|

| Soil type | Clay outperforms sand by 40% |

| Electrode size | Doubling surface area increases current |

Safety and lifespan vary too. Proper grounding prevents voltage leaks, while zinc anodes last 2–3 years. Regulations may apply for large installations.

Conclusion

The future of clean energy lies beneath our feet. Soil-based systems prove that sustainability and affordability can go hand in hand. With minimal upkeep and eco-friendly materials, they offer a practical source for off-grid needs.

Innovation continues to push boundaries. From DIY projects to large-scale applications, these setups inspire communities to rethink energy access. Education and policy support will drive wider adoption.

Ready to experiment? Start small—try powering a garden light or sensor. Every step toward renewable solutions counts. Together, we can turn the ground beneath us into a brighter battery for tomorrow.